Ingredient List and Manufacturing Process

Low fat mozzarella cheese nutrition – The creation of low-fat mozzarella, a culinary marvel born from the delicate dance of milk solids and fat reduction, unveils a fascinating process. This journey, from carefully selected ingredients to the final, creamy product, is a testament to both scientific precision and artisanal skill. Understanding this process illuminates the nuances that distinguish it from its full-fat counterpart.

The quest for a lighter, yet equally satisfying, mozzarella necessitates a careful selection of ingredients and a meticulous manufacturing process. The result is a cheese that retains the signature stretch and melt, while offering a reduced calorie profile.

Typical Ingredient List for Low-Fat Mozzarella

A typical ingredient list for low-fat mozzarella cheese reveals a composition carefully engineered to maintain flavor and texture while minimizing fat content. The precise proportions may vary depending on the manufacturer and specific recipe, but the core components remain consistent. These components work in concert to deliver a product that satisfies the palate while adhering to dietary restrictions.

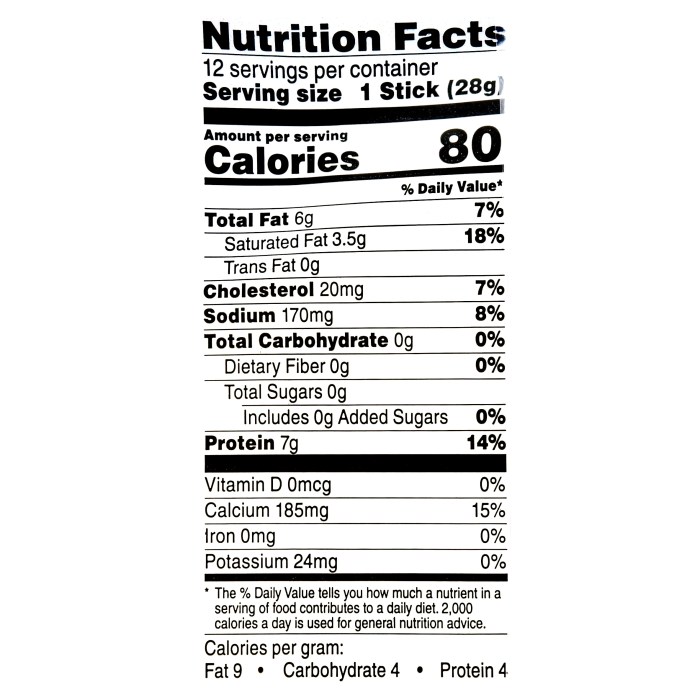

Low-fat mozzarella is a good option if you’re watching your calories and fat intake. However, comparing it to other cheesy snacks can be insightful. Check out the nacho cheese doritos nutrition label to see the stark difference in fat and sodium content. You’ll quickly appreciate the lower calorie count and healthier fat profile of low-fat mozzarella after that comparison.

- Pasteurized Part-Skim Milk: The foundation of the cheese, providing the necessary proteins and lactose for structure and flavor development. The “part-skim” designation signifies a reduction in fat content compared to whole milk.

- Cheese Cultures: These carefully selected bacteria are the catalysts for fermentation, transforming the milk sugars into lactic acid. This process is crucial for the development of the cheese’s characteristic flavor and texture.

- Salt: Salt plays a multi-faceted role. It enhances flavor, controls the growth of unwanted microorganisms, and influences the texture of the final product.

- Enzymes (e.g., Rennet): These enzymes coagulate the milk proteins, separating the curds from the whey. This step is essential in cheesemaking, marking the transition from liquid milk to solid cheese.

- Optional Ingredients: Depending on the specific recipe, manufacturers may include other ingredients such as stabilizers, emulsifiers, or acidity regulators to enhance texture, shelf life, and overall quality.

Manufacturing Process of Low-Fat Mozzarella

The transformation of milk into low-fat mozzarella is a carefully orchestrated process involving several key steps. Each stage contributes to the final product’s unique characteristics, requiring precise control of temperature, time, and ingredient ratios. This meticulous approach ensures consistency and quality.

- Milk Standardization: The fat content of the part-skim milk is carefully adjusted to achieve the desired level for the low-fat mozzarella. This step is crucial for controlling the final product’s fat and calorie content.

- Pasteurization: The milk is heated to a specific temperature to eliminate harmful bacteria and extend the shelf life of the final product. This ensures safety and quality.

- Culturing: Cheese cultures are added to the pasteurized milk, initiating the fermentation process. This process contributes to the development of flavor and acidity.

- Coagulation: Rennet or other coagulating enzymes are added to the cultured milk, causing the milk proteins to coagulate and form curds. This step is vital for separating the curds from the whey.

- Cutting and Cooking: The curds are cut into smaller pieces and cooked to expel whey and further develop texture. The size of the curd cuts influences the final cheese texture.

- Stretching and Shaping: The cooked curds are stretched and shaped into the characteristic form of mozzarella cheese. This process is critical for achieving the desired elasticity and texture.

- Salting and Packaging: The formed mozzarella is salted to enhance flavor and inhibit microbial growth. Finally, it is packaged for distribution.

Comparison of Low-Fat and Full-Fat Mozzarella Manufacturing Processes, Low fat mozzarella cheese nutrition

While both low-fat and full-fat mozzarella share fundamental manufacturing steps, key differences arise primarily in the initial milk selection and fat management. These differences significantly impact the final product’s characteristics and nutritional profile. The essence of the difference lies in the initial fat content of the milk used and the subsequent steps taken to manage it.

- Milk Type: Full-fat mozzarella utilizes whole milk, while low-fat mozzarella employs part-skim milk. This fundamental difference dictates the entire manufacturing process and the final product’s attributes.

- Fat Removal: In low-fat mozzarella production, steps are taken to remove or reduce the fat content of the milk before or during the cheesemaking process. This may involve skimming or other separation techniques. Full-fat mozzarella retains the natural fat content of the whole milk.

- Texture and Flavor: The reduced fat content in low-fat mozzarella can subtly alter the texture and flavor profile compared to its full-fat counterpart. While manufacturers strive to minimize these differences, some variations are inevitable.

Storage and Shelf Life

The fate of your low-fat mozzarella, a culinary chameleon capable of transforming the simplest dish into a masterpiece, rests heavily on proper storage. Neglect this crucial step, and you risk witnessing the tragic decline of this dairy delight from creamy perfection to a disappointing, inedible mess. Understanding the nuances of preservation is paramount to enjoying its full potential.Proper storage of low-fat mozzarella is a delicate dance between temperature and time, a waltz with the elements to prevent premature spoilage.

The enemy is not just time, but also temperature fluctuations, excessive moisture, and exposure to air, all of which can hasten its deterioration. A well-executed storage strategy will dramatically extend its lifespan, ensuring that each slice delivers the expected taste and texture.

Identifying Spoilage

Recognizing the telltale signs of spoilage is crucial to preventing foodborne illness. Look for changes in appearance, texture, and smell. A significant change in color, from the pristine white or pale yellow of fresh mozzarella to a grayish or yellowish hue, is a strong indicator of spoilage. Similarly, the texture should remain firm and springy; a slimy or sticky consistency signals the beginning of bacterial growth.

Finally, trust your nose; a sour or unpleasant odor is an undeniable sign that the cheese has passed its prime. Discard any mozzarella exhibiting these signs immediately.

Maximizing Shelf Life

To maximize the shelf life of low-fat mozzarella, consider these crucial factors. First, always refrigerate the cheese immediately upon purchase. The refrigerator’s consistently cool temperature slows down the growth of spoilage bacteria. Second, store the mozzarella in its original packaging or tightly wrapped in plastic wrap or aluminum foil to prevent it from drying out and absorbing odors from other foods.

For longer-term storage (up to a week), consider vacuum sealing the cheese. This method minimizes exposure to air and moisture, significantly extending its shelf life. Remember, the colder the temperature, the slower the rate of spoilage.

Storage Best Practices

The following guide provides a concise yet comprehensive overview of best practices for storing low-fat mozzarella to maintain its quality and extend its shelf life.

- Refrigerate Immediately: Upon purchasing, immediately refrigerate the mozzarella at a temperature between 35°F and 38°F (1.7°C and 3.3°C).

- Proper Packaging: Store in its original packaging or tightly wrap it in plastic wrap or aluminum foil to prevent air exposure and moisture loss.

- Avoid Temperature Fluctuations: Keep the cheese in a consistent, cool environment. Avoid placing it near the door of the refrigerator, where temperature fluctuations are most significant.

- Vacuum Sealing for Extended Storage: For longer shelf life, consider vacuum sealing the cheese before refrigeration.

- Inspect Regularly: Check the cheese regularly for any signs of spoilage, such as changes in color, texture, or odor.

Question Bank: Low Fat Mozzarella Cheese Nutrition

Can low-fat mozzarella be used in baking?

Yes, but keep in mind it might have a slightly different melt and texture compared to full-fat mozzarella. You may need to adjust recipes accordingly.

Is low-fat mozzarella suitable for people with lactose intolerance?

No, it still contains lactose. Individuals with lactose intolerance should opt for lactose-free alternatives.

How long does low-fat mozzarella last after opening?

Properly stored in the refrigerator, opened low-fat mozzarella typically lasts for 3-5 days. Look for signs of mold or off-odors before consuming.

Does low-fat mozzarella have less protein than full-fat mozzarella?

The protein content difference is usually minimal. The reduction primarily comes from the fat content.